At Cayuga Milk, we go beyond industry requirements to ensure the highest levels of quality, safety, and sustainability in dairy manufacturing. Through advanced processes and strict quality controls, we consistently deliver products that exceed expectations.

Our facility meets and exceeds global standards, holding certifications including Grade A, OU Kosher, Halal, SQF Level III, USDA approval, and Sedex® approval. Our milk quality surpasses EU regulations and is 100% compliant with animal welfare standards.

Our Process

Quality Nutrition

Milk from Cayuga Milk Ingredients’ farms is tested for antibiotic residues, unloaded, pumped into holding tanks, and stored at less than 36°F. The milk is processed within 24 hours.

Separation

Our state-of-the-art separation system enables us to control multiple aspects of the process to provide our customers with consistently high-quality milk ingredients for their specific applications.

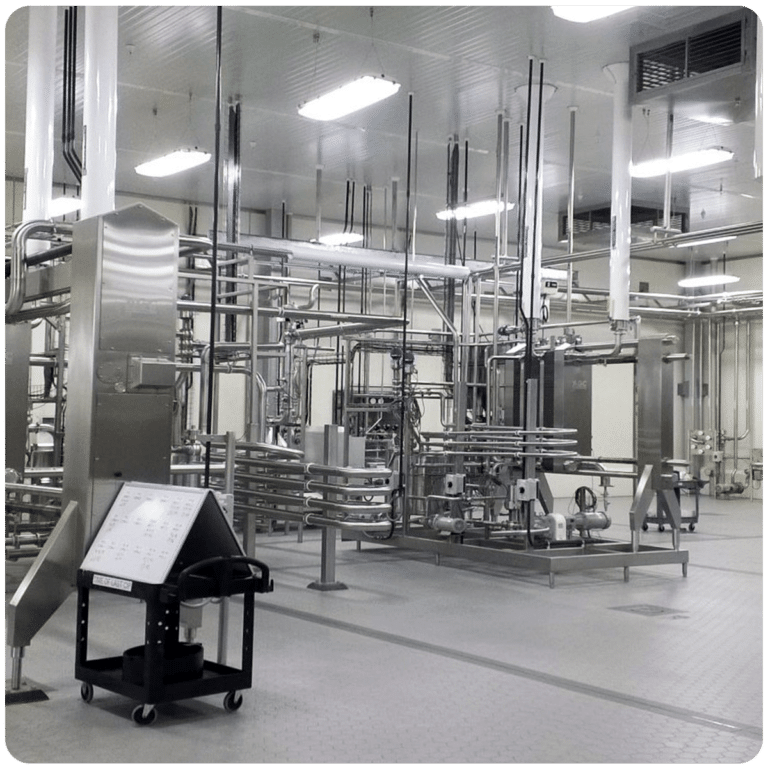

Pasteurization

At Cayuga Milk, our system ensures that our milk reaches and maintains the appropriate pasteurization temperature for the appropriate time period before continuing to the next step of production.

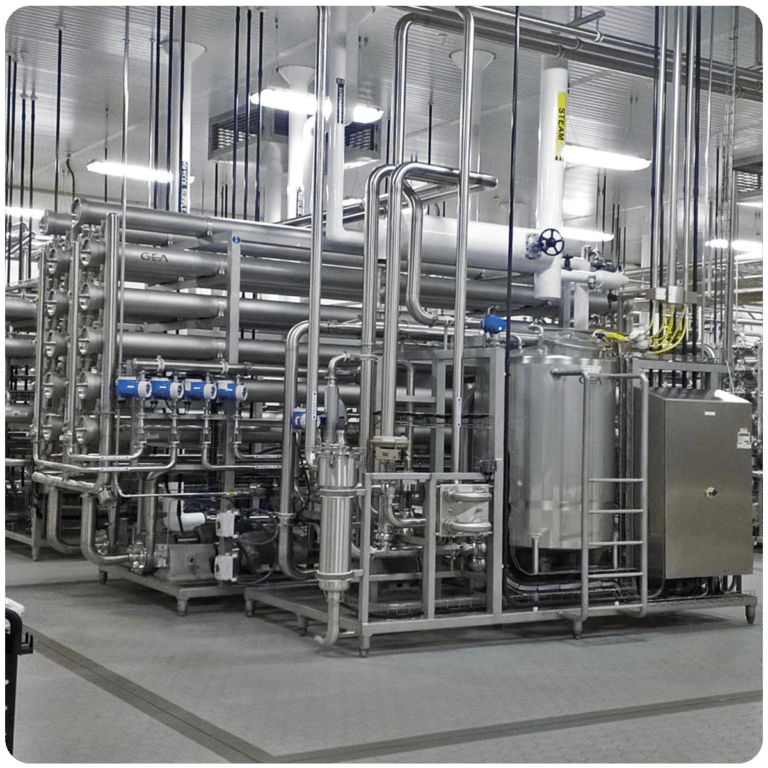

Filtration

Our filtration system ensures the purity and high quality of our milk ingredients, while also enabling us to maximize their nutritional value and unique functional profile.

Evaporation

A key component in manufacturing many of our milk ingredient products, Cayuga Milk’s evaporation system is designed for efficiency, minimal environmental impact, and most importantly, quality.

Spray Drying

The very latest technologies in Cayuga Milk’s manufacturing facility include spray dryers designed to limit contamination and maintain product integrity. These dryers are significant for producing our low heat and medium heat powders, and concentrated products.

Packaging

At Cayuga Milk, our packaging department adheres to extremely intricate protocol according to milk product specifications, unique customer requirements, and governing regulations and guidelines.

Waste Water Treatment

Our sustainability initiatives include waste management with an on-site combination of anaerobic/aerobic waste water treatment facility. It represents one aspect of our 5S methodology to continually improve operations.